Copia Automation is a customer of Business Reporter.

In the manufacturing industry, these are both the most favorable and the most challenging times.

Although the industry is generally on the rise, there are various challenges on the horizon, both new and old. These include inflation, economic uncertainty, a shortage of skilled workers, ongoing supply chain problems, and the risk of cyber attacks. As a result, manufacturers are finding it difficult to maintain stability. Implementing a DevOps approach to industrial automation is a practical solution for manufacturers to mitigate these challenges and ensure continued success in the future. Industrial DevOps combines traditional industrial automation with contemporary software development methods, creating a perfect synergy.

Continuing to move forward.

One of the most important responsibilities for manufacturers is to ensure consistent production. Unforeseen events such as political turmoil, natural disasters, or other localized issues can cause operational disruptions. Regardless of the cause, this can lead to a halt in productivity and significant financial setbacks.

In modernized factories, where production is automated to increase speed and efficiency, any interruptions to the manufacturing process can have a negative impact on stock prices and the company’s reputation. A well-known car company experienced a shutdown at multiple assembly plants due to a malfunction in their system for ordering parts. This was caused by a recent software update, highlighting how the same technology that aids us can also hinder us.

As the leader of Copia Automation, I witness the ease at which manufacturing operations can be disrupted. However, I also understand that risks can be minimized by providing teams with appropriate tools, allowing them to track and monitor code changes, and empowering them to quickly identify and resolve issues. By implementing effective strategies from the software development model in industrial automation processes, plant operations can be effectively managed, leading to improved efficiency, stability, and security, and quicker recovery from system disruptions.

Can you explain the concept of Industrial DevOps?

DevOps is a popular set of methods that has transformed the processes of software development teams, enabling them to work faster and more effectively. Key elements of a DevOps setup include collaborative tools and guidelines for allocating tasks, managing code development, storing data, and testing and releasing software. These practices facilitate continuous progress in development and enable swift detection and resolution of mistakes.

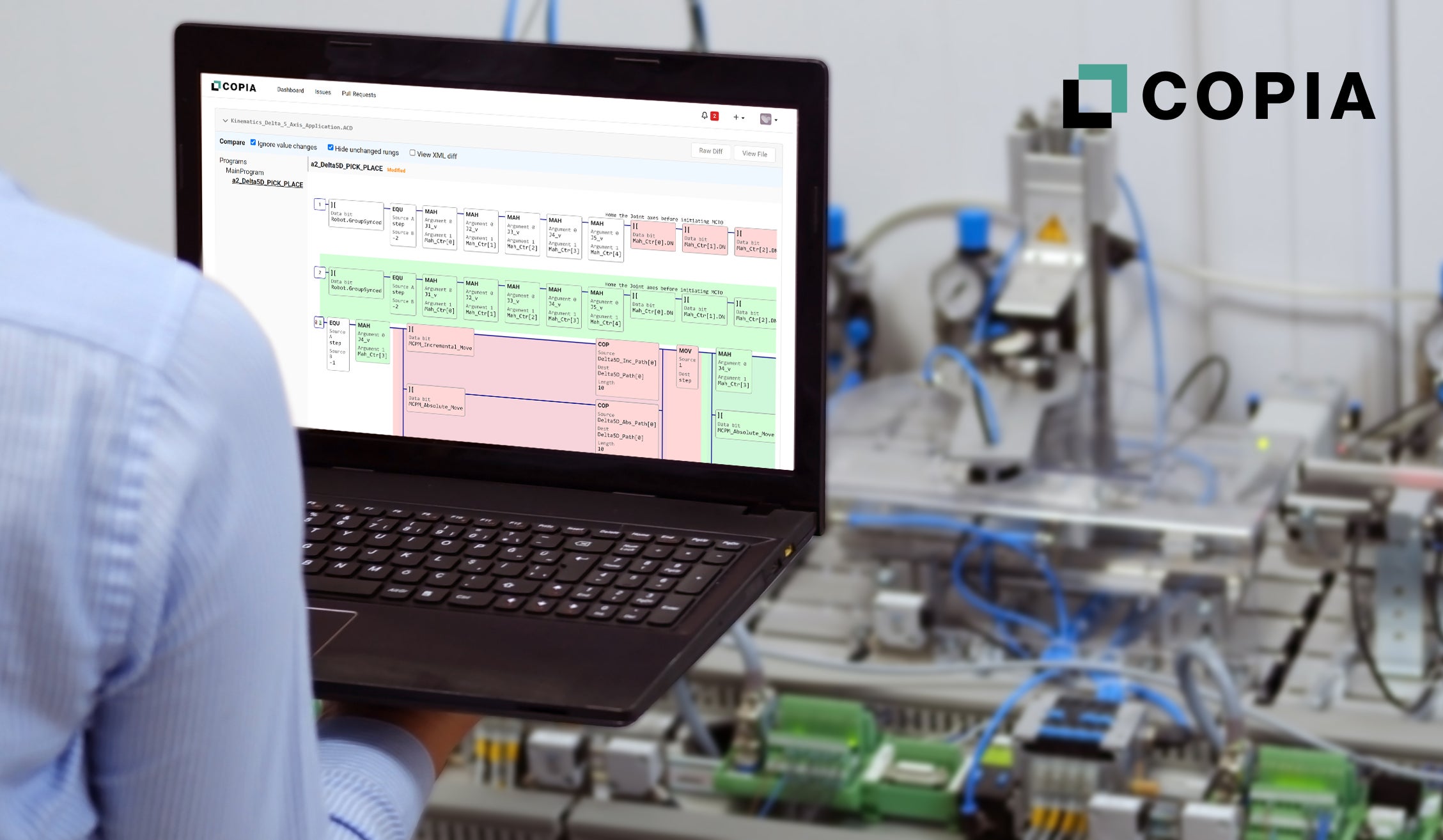

Industrial DevOps applies these concepts to the industrial automation process, providing powerful tools and a highly defined, collaborative environment for managing automated manufacturing systems. From design and programming of automated components and storage and management of source code, to testing, production and troubleshooting, Industrial DevOps provides a single source of truth for overseeing your industrial automation workflow. It enables the faster deployment and maintenance of robotic devices, programmable logic controllers (PLCs) and other equipment, and provides the ability to proactively anticipate and recover from crippling problems and outages.

What is the appearance of Industrial DevOps?

A DevOps platform designed for industrial use, like Copia, offers a comprehensive source control repository for automating projects. This can be useful for tasks such as regulating the baking time for cookies or determining the thickness of paint on a car door using PLCs. Copia allows for effective monitoring and precise management of PLC code development. When it’s time to implement the updated PLC, it can easily be swapped in, tested, and modified with precision within a single platform that supports multiple vendors. Additionally, Copia offers reliable source control and change management for PLCs and control devices.

Farewell, monotonous work: Industrial DevOps streamlines processes and eliminates the need for manual and repetitive tasks.

Any changes made to the code in the future will be automatically reflected in the source control repository, preventing any errors that may occur from manual updates. Automatic alerts will also be sent for any unauthorized changes. In today’s industrial landscape, it is crucial to protect control data through reliable backup strategies. While IT departments have traditionally prioritized backing up business data, the manufacturing environment has relied heavily on physically connecting PCs to PLCs for backups, which were not regularly or consistently performed. Even with manual backup processes in place for machines and devices, as well as various automation programs, it is impossible to determine if code has been altered, when, why, or by whom, leaving the system vulnerable.

Industrial DevOps streamlines and automates these labor-intensive tasks, allowing for a clear representation of the code being executed on the factory floor, facilitating easy comparison with previous versions. It also allows for customized alerts to be sent when changes are detected and for backups to be scheduled and executed as needed. This enhanced visibility and management expedites the process of identifying and resolving issues, minimizing downtime and facilitating swift recovery.

In summary, Industrial DevOps speeds up and improves the development and upkeep of industrial automation processes. This approach also offers long-term benefits, such as reducing operational risks and increasing efficiencies, for businesses.

Sometimes, I encounter producers who are hesitant to switch to this modern approach of supervising plant activities. The expenses and efforts involved in adopting a new system or method can be overwhelming for some. I empathize with their concerns. However, with a shortage of skilled workers, more companies constructing new plants to relocate their production, and the need for quicker and more effective production due to tighter profits, the real danger lies in not taking any action.

To gain further insight into Copia and enhance the efficiency of your industrial automation procedures, please visit copia.io.

The website “Independent” is a UK-based news platform.

The news platform “Independent” is based in the UK.